in the present production landscape, the allure of a flawlessly finished products frequently overshadows a important thought: the wellness and security on the persons to blame for bringing that merchandise to daily life. the whole world of electroless copper plating, essential for numerous industries from electronics to automotive, is not any exception. While the procedure provides the desired conductivity and corrosion resistance, Furthermore, it offers A selection of possible dangers to staff who manage the specialized plating chemical substances involved. this text delves into the usually-missed region of employee protection in copper plating, specializing in the challenges affiliated with chemicals like MPS Sodium (3-Mercaptopropanesulphonate) and outlining functional techniques to mitigate these hazards and ensure a healthier, a lot more sustainable Doing the job environment. For corporations seeking a trustworthy electroless copper plating manufacturer, understanding these safety criteria is paramount.

Table of contents:

Understanding the Chemical Landscape - MPS Sodium and its Attributes

publicity Pathways - How staff occur into Speak to

The Power of particular Protective Equipment (PPE)

Engineering Controls - creating a Safer ecosystem

unexpected emergency Response and Preparedness - preparing for the sudden

extensive-phrase wellness Monitoring - Addressing Continual Exposure

Streamlining procedures with Automation - Reducing Human mistake

comprehension the Chemical Landscape - MPS Sodium and its Homes

three-Mercaptopropanesulphonate (MPS Sodium), typically made use of as being a brightener and accelerator in copper plating baths, is a strong chemical compound that presents a novel list of troubles. to completely address worker security, It really is very important to know the inherent properties of the substance:

Irritation probable: MPS Sodium, in its concentrated form, can be an irritant on the pores and skin, eyes, and respiratory technique. The presence of risky sulfur-that contains compounds, specifically thiol groups (-SH), can launch noticeable odors which could lead to distress or respiratory irritation in delicate people today.

Corrosivity problems: dependant upon the formulation along with the pH with the plating bath, MPS Sodium-made up of solutions might show corrosive Houses. This is especially suitable in electroplating procedures that entail acidic or alkaline electrolytes, which might exacerbate the corrosive effects.

Potential for harmful Impurities: The production strategy of MPS Sodium can in some cases bring on the existence of trace impurities, including unreacted sulfides or weighty metals. though these impurities are typically existing in tiny portions, their extended-phrase health results must be considered.

Exposure Pathways - How staff appear into Make contact with

pinpointing potential exposure pathways is another very important stage in utilizing successful protection protocols. staff may be subjected to MPS Sodium and also other plating chemical substances as a result of several routes:

Inhalation: Vapors or aerosols produced in the plating course of action, particularly when the plating tub is heated, may be inhaled. The volatility of certain components within the plating solution, like natural and organic amines or residual solvents, can lead to airborne contamination.

Skin Make contact with: Direct pores and skin contact with concentrated MPS Sodium remedies, plating baths, or contaminated surfaces is a substantial hazard. Even quick or seemingly insignificant Speak to can lead to irritation, dermatitis, or chemical burns, dependant upon the focus and period of exposure.

Ingestion: While considerably less widespread, accidental ingestion can come about due to inadequate hygiene techniques during the office, for instance having or ingesting in locations in which chemical substances are handled.

Eye Make contact with: Splashes or accidental connection with plating remedies could cause significant eye irritation or even long lasting harm if not dealt with instantly.

the strength of personalized protecting gear (PPE)

personalized protecting machines (PPE) kinds the first line of protection against chemical exposure. deciding on the suitable PPE, and making certain its correct use, is vital.

Hand safety: picking out the suitable glove substance is essential. normal latex or nitrile gloves may not offer ample protection against MPS Sodium and various substances Utilized in electroplating. Gloves crafted from butyl rubber, neoprene, or other chemically resistant materials are frequently vital. The glove's thickness and cuff duration also needs to be regarded as to provide adequate barrier safety.

Respiratory security: with regards to the focus of airborne contaminants, respiratory protection can be needed. This could range between basic dust masks to respirators Geared up with ideal cartridges or filters intended to clear away natural vapors, acid gases, or particulates.

Eye and encounter security: basic safety glasses with facet shields or, a lot better, a full encounter defend must be worn to protect from splashes or accidental connection with plating methods.

Protective clothes: Chemical-resistant aprons or coveralls need to be worn to safeguard the skin from contact with chemicals.

Engineering Controls - creating a Safer surroundings

although PPE is critical, engineering controls give you a a lot more sustainable and successful method of reducing worker publicity. These controls target modifying the operate ecosystem to lessen or eliminate dangers.

Ventilation techniques: neighborhood exhaust ventilation (LEV) devices are necessary in electroplating facilities to capture and remove airborne contaminants at their source. These techniques should be designed to seize vapors, fumes, and aerosols created over the plating approach. typical routine maintenance and monitoring of air flow units are vital to be sure their efficiency.

Enclosure and Isolation: Enclosing or isolating plating operations can avert the unfold of contaminants and lower the potential risk of publicity. this will likely include employing enclosed plating tanks or automatic methods that lower the necessity for guide managing of chemicals.

Spill Containment: employing spill containment measures, including installing drip trays, bunds, or spill containment boundaries, can stop spills from spreading and contaminating the perform setting.

Automated methods: employing automated methods for chemical handling, for example automatic dosing methods or robotic arms, can limit the need for handbook intervention and lessen the chance of publicity.

unexpected emergency reaction and Preparedness - scheduling to the sudden

Despite the best preventive actions, incidents can however transpire. possessing a very well-described emergency response strategy in position is very important for minimizing the influence of incidents.

Emergency methods: distinct and concise crisis processes needs to be developed and communicated to all employees. These processes ought to outline the techniques to absorb the event of a spill, publicity, or other crisis.

initial support: enough 1st support facilities, including eyewash stations and emergency showers, really should be available within the office. staff must be properly trained in standard initially support procedures, including how to answer chemical exposures.

Spill reaction Kits: Spill reaction kits that contains acceptable absorbents, neutralizers, and personal protecting gear needs to be readily available in regions exactly where chemicals are managed.

common Drills: Conducting frequent crisis drills might help making sure that personnel are aware of unexpected emergency techniques and will respond correctly from the function of an incident.

very long-Term overall health checking - Addressing Persistent Exposure

The likely prolonged-time period wellness outcomes of exposure to plating chemicals, even at very low concentrations, shouldn't be overlooked.

Exposure checking: common monitoring of worker exposure degrees to plating chemical compounds might help to discover prospective overall health check here hazards and be certain that Manage steps are efficient.

wellness Surveillance: utilizing a wellness surveillance method, together with periodic health care examinations and biological monitoring, may also help to detect early signs of health issues connected to chemical exposure.

history preserving: sustaining precise information of worker publicity concentrations, wellbeing surveillance information, and any incidents or incidents might help to identify trends and designs and To judge the performance of Handle actions.

Worker Education: Providing employees with comprehensive information about the opportunity wellbeing results of exposure to plating substances and the value of following basic safety strategies can help to advertise a tradition of protection and stop long-phrase health conditions.

Streamlining Processes with Automation - Reducing Human Error

Minimizing human error is often a essential facet of enhancing protection. automatic processes offer major rewards in this spot.

Pre-combined remedies: utilizing pre-blended chemical remedies can eliminate the need for guide mixing and decrease the potential risk of glitches in concentration.

automatic Dosing programs: automatic dosing devices can be certain that substances are added to plating baths in the proper proportions and at the right times, reducing the potential risk of chemical imbalances or hazardous reactions.

Robotic managing: applying robotic arms to take care of chemicals can reduce the need for handbook dealing with and decrease the risk of exposure.

Closed-Loop Management: employing closed-loop Regulate devices that check and change plating bath parameters can assist to maintain best plating problems and forestall the Develop-up of dangerous substances.

segment eight: The purpose of Suppliers in advertising protection

Chemical suppliers Enjoy a crucial part in advertising and marketing worker security by giving comprehensive specifics of the hazards affiliated with their products and providing steerage on Harmless handling techniques.

Safety facts Sheets (SDS): delivering exact and up-to-date protection knowledge Sheets (SDS) that include specific information regarding the hazards, handling safety measures, and emergency methods for each chemical item.

Technical assistance: presenting complex help to customers on Secure dealing with procedures, including steering on the choice and use of private protecting machines, air flow programs, and other Regulate actions.

Training packages: Developing and providing training courses for staff within the Risk-free dealing with of substances, such as fingers-on demonstrations and sensible exercise routines.

Product Stewardship: employing product or service stewardship systems that encourage the accountable administration of chemical compounds all through their lifecycle, from manufacturing to disposal.

Prioritizing worker health and fitness and basic safety in electroless copper plating is not really basically a make any difference of compliance; It really is an expenditure within the long-time period sustainability and accomplishment of any Group. By understanding the inherent hazards connected to chemical substances like MPS Sodium, implementing strong control measures, and fostering a tradition of protection, corporations can develop a healthier plus much more productive get the job done natural environment.While there are several plating chemical compounds company on the market, some, like Fengfan Trade, are dedicated to providing don't just high-excellent chemical substances but will also complete help and methods that will help shoppers make sure the Harmless and responsible use in their products and solutions. picking a lover that prioritizes the two effectiveness and safety is an important phase towards developing a brighter, more healthy future with the plating field.

Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Andrea Barber Then & Now!

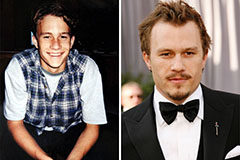

Andrea Barber Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!